ABLE – Data Collector Accelerator

ABLE accelerates digital transformations with advanced data collection for OEE and MES solutions. By deploying Sage Clarity’s ABLE application in your environment you can accelerate and drive OEE uplift, avoid problems before they occur, and reduce engineering time by up 70%. If you are looking for real-time OEE data that can be seamlessly integrated into your existing ERP, CMS, or Production Management system, ABLE Data Collection Accelerator App is for you.

ABLE models machines and production lines with no modification to PLC logic. Line and machine states, counts, root cause are all coalesced in our logic engine and published via Kepware to Epicor Informance, Wonderware, and other MES systems.

This non-intrusive method combined with our advanced diagnostic and validation tools allows for remote deployment. Our root cause algorithm produces 20% higher data fidelity creating more actionable intelligence.

Watch our video to learn more about how ABLE™ works »

Benefits of ABLE:

- ABLE integrates IoT edge data into business systems—MES, SCADA, and ERPs.

- Production line modeling finds the root cause of downtime so you’ll be up and running quickly.

- Auto-tagging reduces integration costs by 50%, so you can achieve a faster return on investment.

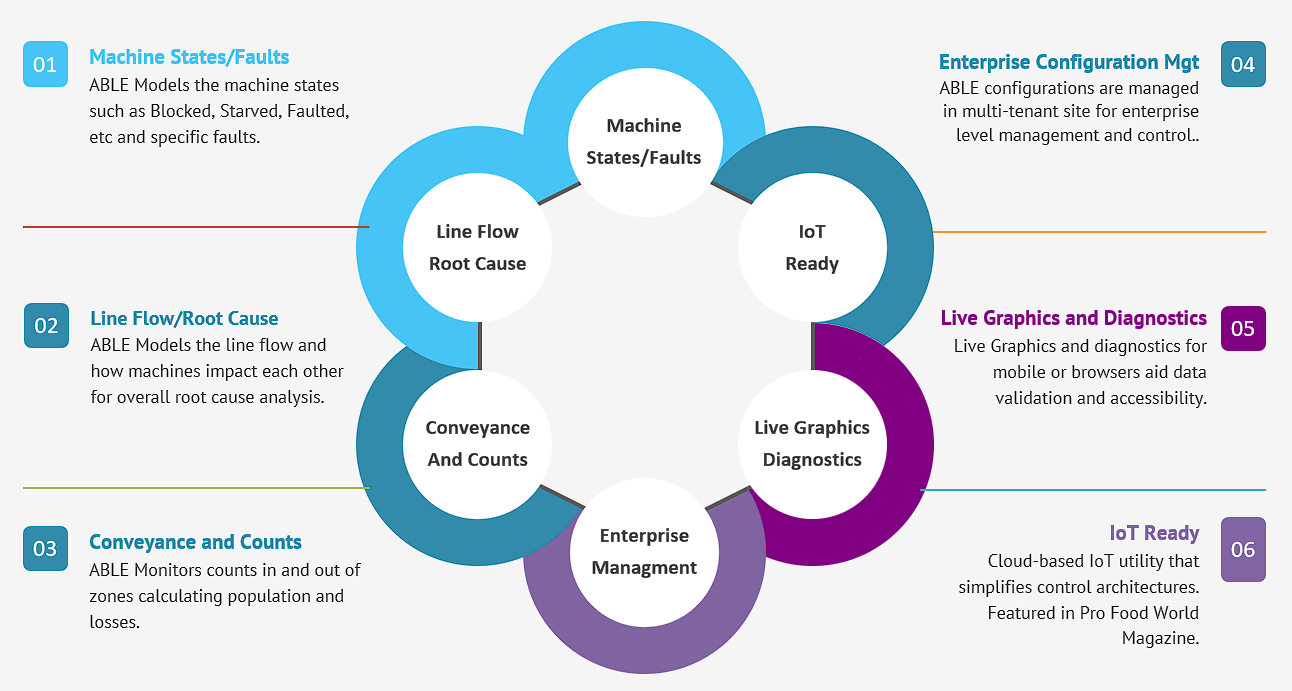

ABLE™ Capabilities

How ABLE™ Works

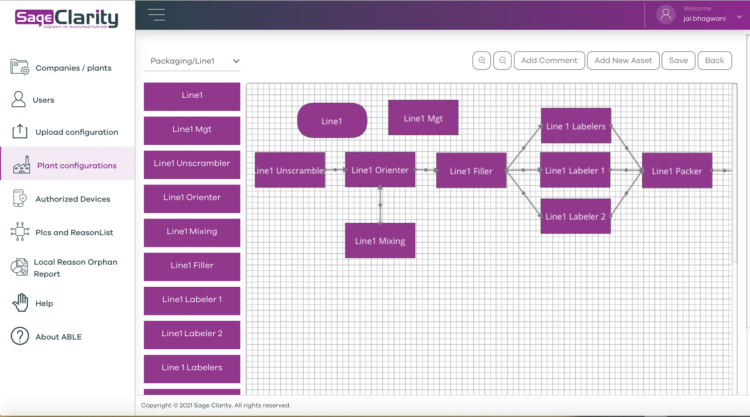

Cloud Configuration

As simultaneous or overlapping events occur, ABLE’s logic engine can determine the root cause for downtime at the constraining asset.

- Supports a corporate PLC standardization strategy

- Simplifies data acquisition & control architectures

- Enterprise configurations that can be copied from line to line and plant to plant.

Production Line Modeling

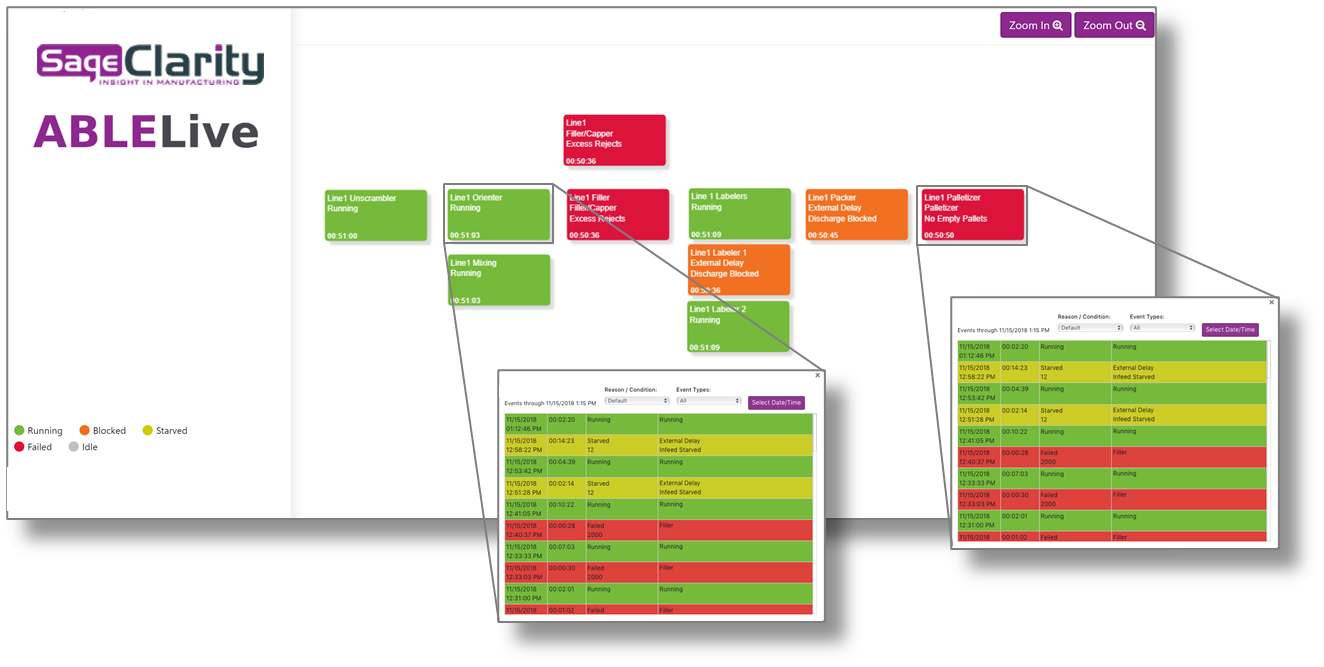

ABLE™ actively monitors your production lines and provides root-cause analysis in real time.

- Modular modeling of machine centers, each with simple logic engine to determine state

- Modeling of line flow to determine root cause

- A runtime engine executes the root cause logic in real-time, imbedded as middleware in the MES system.

Root Cause Analysis

- Understand the DNA of a production line

- How assets are inter-related

- See the progression of downtime as it propagates up and down the line

ABLE™ Live Analytics

- Analytics available on shop floor HMIs

- Availability, MTBF, MTTR by work center

- Detailed logging of event history

Better Together. ABLE™ + Next-Gen Andon

The Power of Our Industry 4.0 Suite

Use ABLE™ as a data pipeline for your manufacturing analytics. Its equipment state analysis can be fed into our next-gen andon system to alert you when production isn’t humming at full speed. Not only will you know a problem exists, but exactly where and what it is.

- ABLE™ edge computing analyzes data from your production line and delivers root-cause analysis when issues arise, and can even predict upcoming production issues.

- Next-gen Andon pushes alerts to the Factory Media Center, shop floor HMIs, and to mobile devices, giving you instant awareness of your production line operations.

- Oneview manufacturing analytics gives you all the KPIs you need in one easy-to-use dashboard.

ABLE™ is Your IIoT Gateway for Cloud Computing

Skip PLC programming. Integrate PLC data directly into your MES & ERP.

ABLE enables transforming IoT data into business systems (MES, SCADA, ERP apps, etc.).

A lightweight, root-cause IoT solution that leverages OPC UA technology and allows enterprises to simplify control architectures. With an OPC and cloud-based configuration solution, you don’t need a concentrator PLC. Connect to each PLC on the line directly and correlate the data across PLCs. Removing data storage and data transformations from PLCs allows enterprises to treat the PLC as an IoT device, simplifying their control architectures.

ABLE is ISA-95 compliant and works with the standard to allow it to determine state logic. ISA-95 is an standard from the International Society of Automation for developing an automated interface between enterprise and control systems.

ABLE is now also SAML 2.0 compliant, ensuring that access to business platforms is easy and more secure.

How your production benefits:

- Less cost – Reduces integration cost for AutoTagging by 50% to provide faster return on investment.

- Less coding – Reduces PLC Programming for AutoTagging by over 80%

- Less miscues – Accurately identifies, tags and reports root causes for line stops, to let you improve line efficiency… more efficiently.

- Less noise – Enhances analytics to specifically identify root cause, not symptoms to build trust in reporting.

- Less hassle – Reduces cost associated with change management by over 80% by housing the code remotely.